To ensure uninterrupted service and the safety of the infrastructure, the monitoring of catenary tensioning is essential for the entire network.

In order to avoid contact wire breaking, in spite of temperature variations, the tension must be constant.

Safety, quality of service and maintenance costs are the main issues

In extreme weather conditions, such as high temperatures, the counterweights are lowered and can reach the stops. This means that the mechanical tension is no longer maintained, the contact wires are no longer horizontal and can break when the pantograph passes or create electric arcs.

To prevent this from happening, on-the-spot verifications and interventions are very frequent but also very costly.

This is why Stimio has deployed a remote overhead line expansion monitoring solution which drastically reduces the number of inspection rounds and at the same time avoids disruption of the service.

Collecting information using a certified connected sensor

Our catenary tensioning monitoring solution can be easily deployed with the help of our Railnode IoT device, which is railway certified. The Railnode is attached to the top of the catenary mast and measures the height of the counterweight.

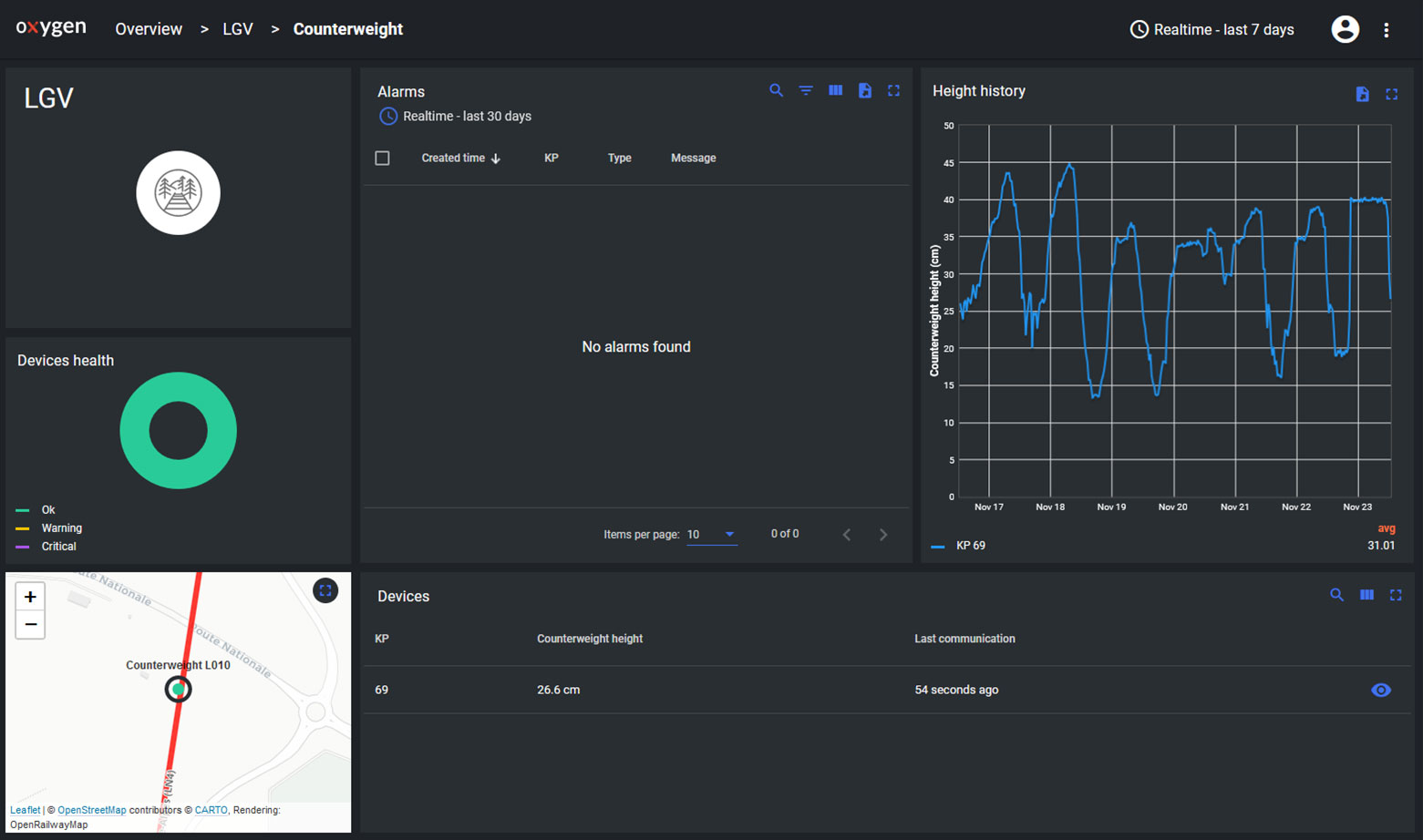

The data is stored, decoded and visualized on our Oxygen Asset Management, enabling the monitoring and prediction of the tension of the catenaries.

The information collected is downloaded wirelessly and, if required, directly into the customer’s third-party information system.

Railnode has a life span of up to five years, is battery operated and requires no power cables. Its installation is all the more simplified.

The modularity and swiftness of monitoring overhead line expansion fulfils its objective perfectly by offering rapid implementation without substantial intervention on the equipment.

Counterweight height prediction up to 48 hours in advance

With our IoT solution, from the sensor to the cloud interface, it is possible to optimize maintenance operations thanks to being able to predict the catenary tensioning up to 48 hours in advance on the entire network.

Our turnkey solution allows the creation of a behavioral model of catenary tensioning and counterweight height.

This is of paramount interest: to be able to predict the behavior of the counterweight height upstream and anticipate maintenance actions as accurately as possible.

The platform’s dashboards are especially adapted to the needs of the railway operators and make it possible to create alerts in order to be warned when the height of the counterweight exceeds the defined threshold.

A wide portfolio of railway-certified connected devices

Stimio offers a portfolio of connected devices for the railway industry, covering a wide range of use cases to help operators face their many challenges. In addition to catenary counterweight height and tensioning monitoring, Stimio’s solutions are designed to monitor:

- Remote surveillance of rail temperature;

- Pantograph health and lifting function;

- Monitoring and prediction of sand levels in silos.

Stimio’s end-to-end IoT solutions are already implemented in more than 30 use cases in the railway industry, for rolling stock remote condition monitoring, wayside and signaling concerns.

To learn more

Railnode

Railnode is Stimio's certified rail solution for collecting data and delivering them to Oxygen and business information systems.

Learn more →

Oxygen Asset Management

From device management to visualisation and prediction, Oxygen Asset Management unlocks data’s potential and turn them into intelligent and actionable information.

Lean more →

Let's talk about your concerns

Related news

Rail track monitoring – Real time rail defects monitoring

June, 28th 2022Rail track monitoring - Real time rail defects monitoringRail track monitoring - follow your track geometry and defects remotely and in real time with our IoT solution Railway tracks are permanently subject to numerous constraints, which can be weather...

Monitoring and prediction of sand levels in silos

April, 21st 2022Monitoring and prediction of sand levels in silos The large majority of rail rolling stock, trains, tramways and subways use sand to increase wheel-rail adhesion for traction and braking. Some conditions significantly decrease vehicle adhesion, such...

Stimio to exhibit at Rise of IoT and Big Data in rail 2022

April, 20th 2022The Rise of IoT & Big Data in Rail 2022 We will be physically present as an exhibitor and Bronze Partner at The Rise of IoT and Big Data in Rail 2022 from May 17th – 18th.We will have the opportunity to present our IoT business solutions for...