Pneumatic circuits and their compressors are an essential component of rolling stock. They have multiple functions:

- opening and closing doors,

- engaging brakes and sandboxes,

- suspension management,

- etc.

Passenger comfort and safety are highly dependent on the compressor and its pneumatic circuit operating properly. Nonetheless, the air production equipment on board rail vehicles is subject to harsh operating conditions and very high utilisation rates, making it essential to monitor its health.

Pneumatic air compressors, an essential component in rolling stock operation

Even though air compressors are subject to a regular and preventive maintenance schedule, unfortunately, it is not uncommon for breakdowns to take place between the two interventions.

In addition to compressor breakdowns, air leaks anywhere on the pneumatic circuit can also cause problems for rail operators. These leaks can be both temporary and permanent, and can originate in one or multiple components supplied by the compressor.

No sensors enable the real-time uploading of information on compressor health and use during operation. As a result, clients lack a dynamic view and leaks are only discovered at the maintenance centre and not during train operation. Some compressor leaks may even go unnoticed during inspection due to their intermittent nature.

Testimonial

Maintenance Engineering Manager – KEOLIS LYON (TCL)

Stimio’s real-time monitoring solution for the pneumatic circuit enables us to quickly identify leaks, both permanent and fleeting, in our circuits. This allows us to anticipate and plan our maintenance interventions much more accurately to limit the immobilisation of our vehicules and avoid operating stoppages.

Below is a non-exhaustive list of the negative consequences reported by our clients:

- Immobilisation of the line and train if large leaks in breaks or doors appear,

- Disturbance of traffic and domino effect on other lines and connections,

- Premature deterioration of different components, including the compressor,

- Overburdening of maintenance with unplanned maintenance actions,

- Passenger safety: a major breakdown of the pneumatic system can result in the functional breakdown of essential components, such as doors, brakes, etc.

- etc.

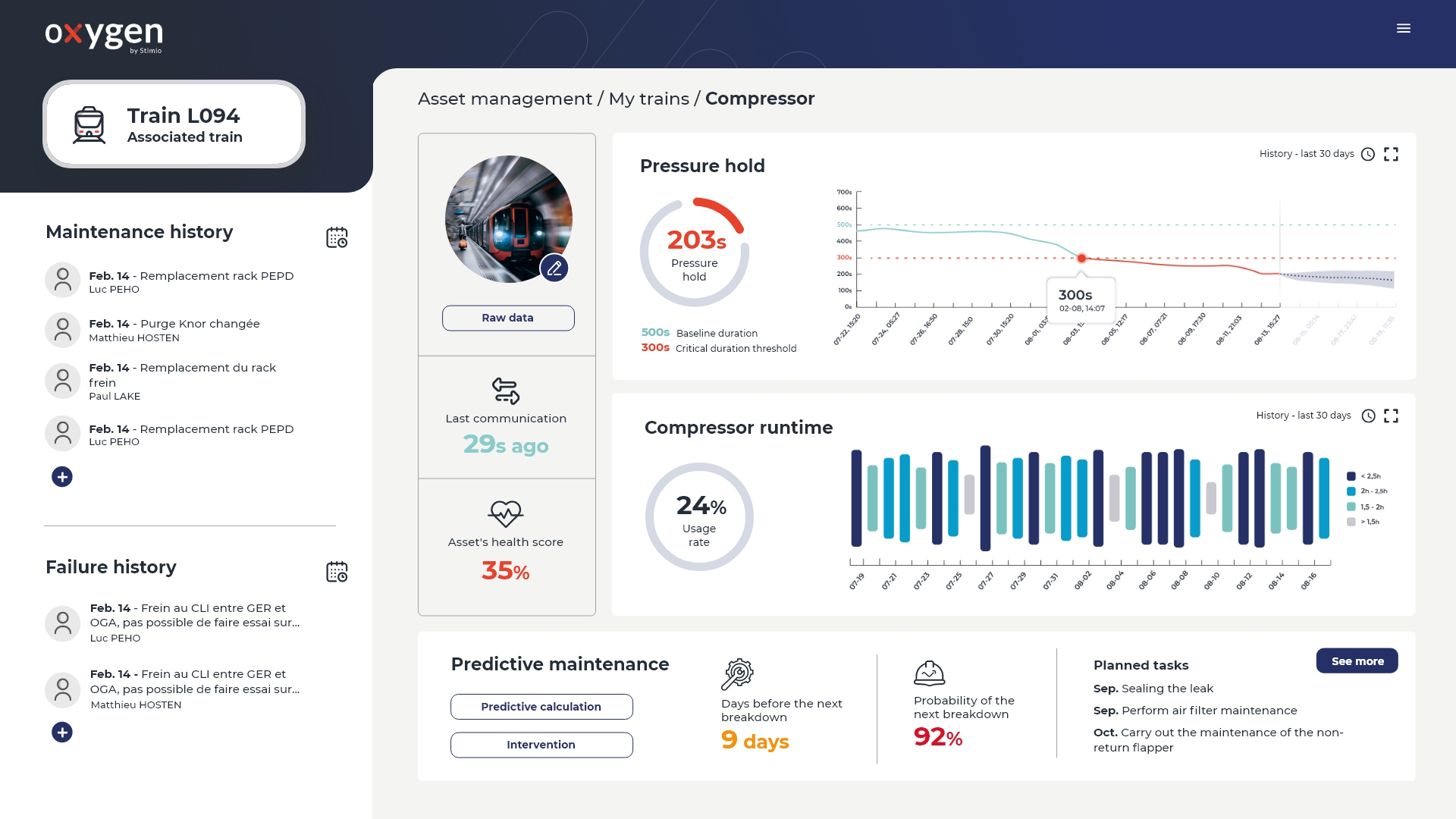

The Oxygen IoT Solution for rail compressor monitoring

To correct these failures, better understand compressor behaviour under real conditions, and improve the quality of service, the continuous, real-time monitoring of compressors is therefore essential. Stimio’s Oxygen Asset Management allows our clients to rapidly resolve these problems while simultaneously offering future possibilities (see “Prediction” below).

A private wireless network can be set up in a few hours. Our Railnode certified rail IoT sensors are installed on compressors to measure on/off activation time. As a result, they allow the compressor to communicate. Moreover, our Railnet IoT gateway is the centrepiece of the private wireless network. It collects sensor data and sends it to the Oxygen Asset Management. We deliver enriched business data that can be directly exploited and integrated into our clients’ IT systems. Data analysis on the Oxygen platform allows to highlight abnormal behaviour, load rates, loading-unloading cycles, etc.

It optimises the planning and anticipation of equipment maintenance.

Prediction

Our Oxygen Asset Management solution makes it possible to analyse the behaviour of the different compressors installed on trains. It is then possible to define and classify this behaviour.

Doing so is of critical utility, as it allows to predict compressor behaviour, detect the early warning signs of breakdowns, and anticipate maintenance actions as accurately as possible.

This requires mathematical modelling and prediction based on data from the compressor fleet combined with the use conditions and features of each compressor (model, age, utilisation rate…).

Combining all of this data allows to define nominal behaviour. Each compressor is then regularly compared to this standard behaviour both in terms of its category and the global population. If there is an abnormal deviation in a parameter, it will be possible to predict when an inspection or repair intervention will be necessary.

Our solution comes with multiple benefits:

Operation:

- Improvement in reliability and operational efficiency,

- Reduction in production losses,

- Quick and easy decision-making enabled by IoT data analysis

Safety:

- Safety of users and maintenance staff.

Maintenance:

- Increased asset lifespan,

- Reduced maintenance costs,

- Compressor maintenance triggered following the analysis of early warning signs.

Brand image:

- Increased customer satisfaction.

Discover the building blocks of our modular solutions

Oxygen Asset Management

From device management to visualisation and prediction, Oxygen Asset Management unlocks data’s potential and turn them into intelligent and actionable information.

Lean more →

Railnode

Railnode is Stimio's certified rail solution for collecting data and delivering them to Oxygen and business information systems.

Learn more →

Railnet

Railnet is our rail certified gateway to connect sensors and on-board equipment for rolling stock, already in operation or new ones.

Learn more →

Predictive maintenance of a rail compressor combining Stimio’s Oxygen Asset Management and IBM’s Maximo solutions.

If you are looking to implement a predictive maintenance project

Related news

Oniti test for articles

September 26th, 2023Oniti test for articles

Stimio to exhibit at SIFER 2023

February, 6th 2023Stimio to exhibit at SIFER 2023We are exhbiting during the new edition of SIFER which will be held from 28 to 30 March 2023 in Lille, Grand Palais. Meet us on stand 1-527 to discuss your projects: assets real-time and remote condition monitoring,...

Operations & IoT – Stimio optimises procurement with Carl Software

January, 9th 2023Operations & IoT - Stimio optimises procurement with Carl SoftwareAt the request of a client, our teams worked on connecting our Oxygen Cloud platform to the CMMS tool used by its teams: Carl Software. Our IoT solution deployed at this client's...